Early days of soil dynamics: Resonant column device, Mononobe-Okabe theory, etc.

Early days of soil dynamics: Resonant column device, Mononobe-Okabe theory, etc.

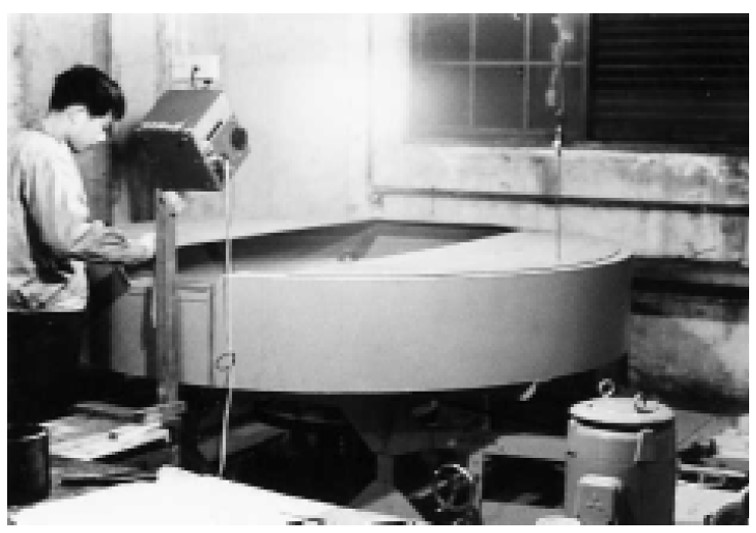

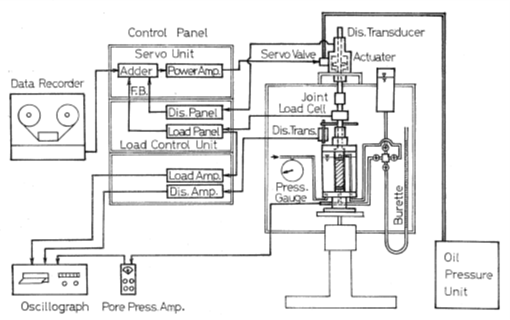

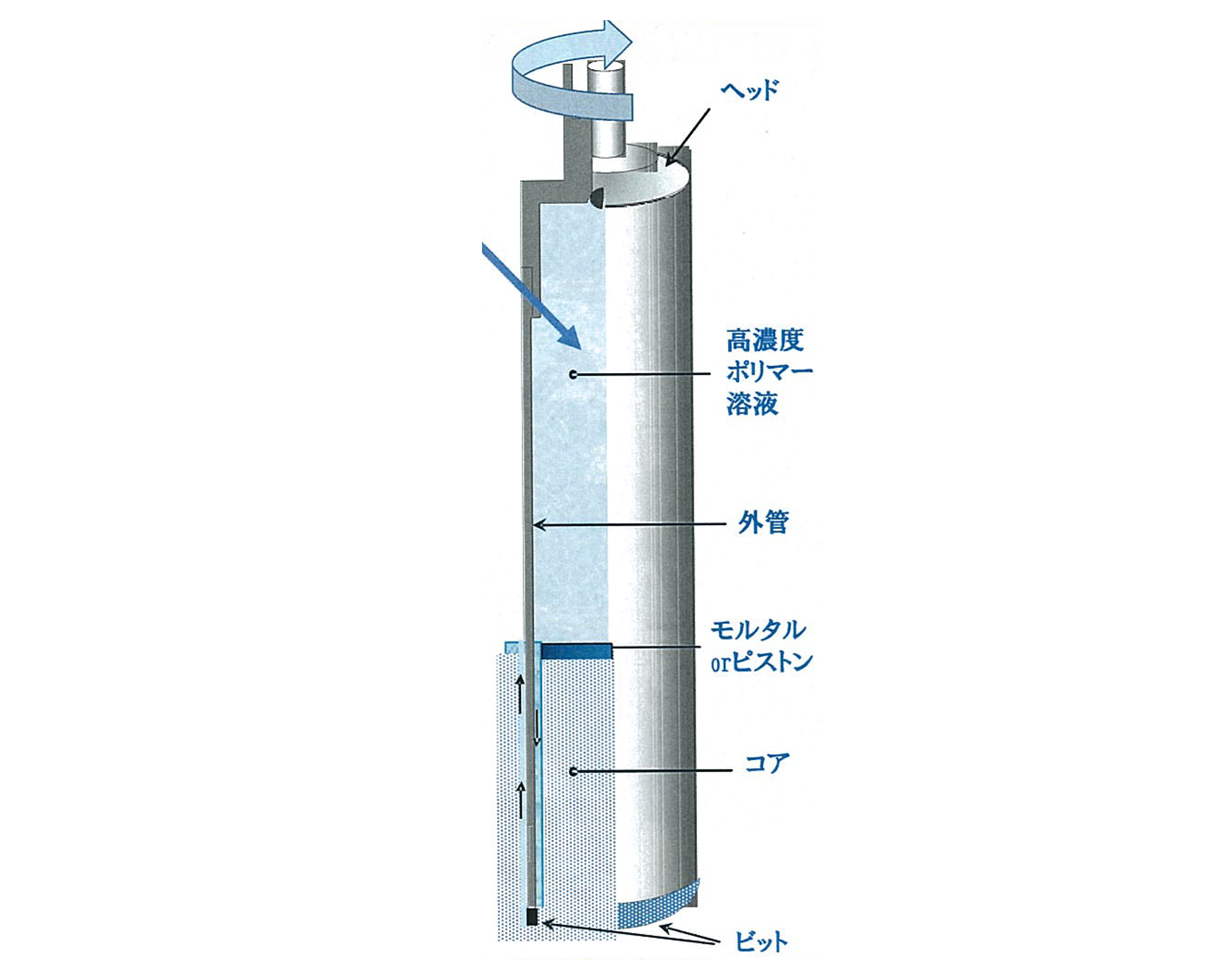

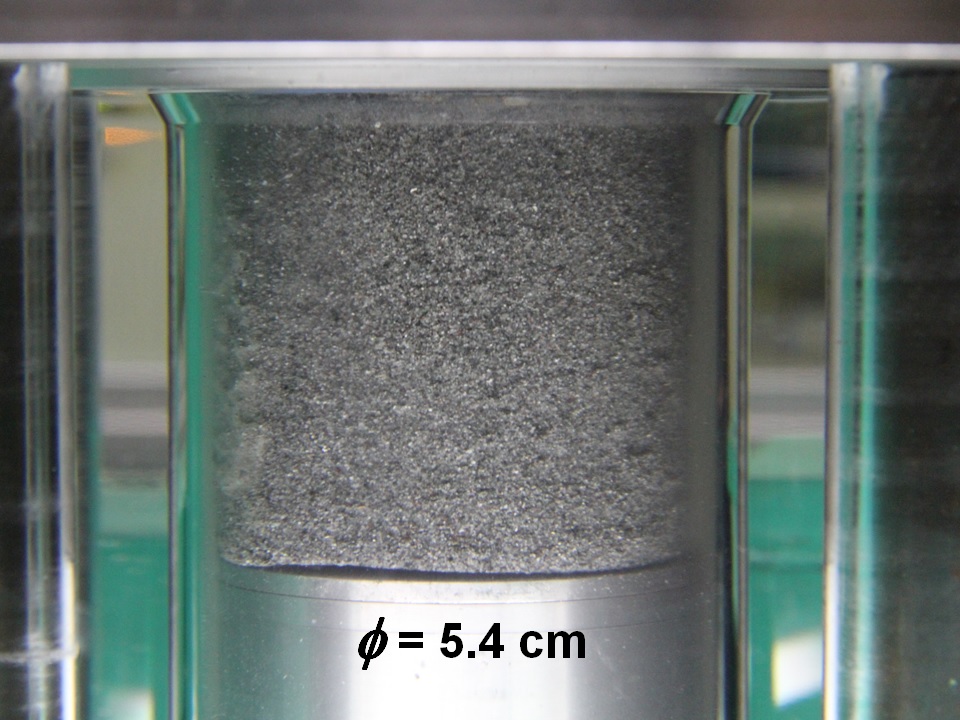

The first resonant column device (Ishimoto & Iida, 1936; © 2021 Earthquake Research Institute, The University of Tokyo.) |

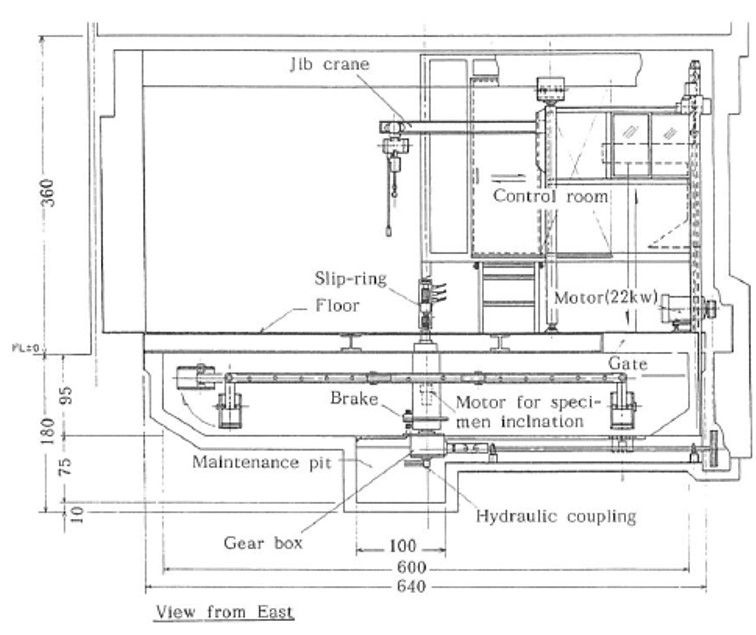

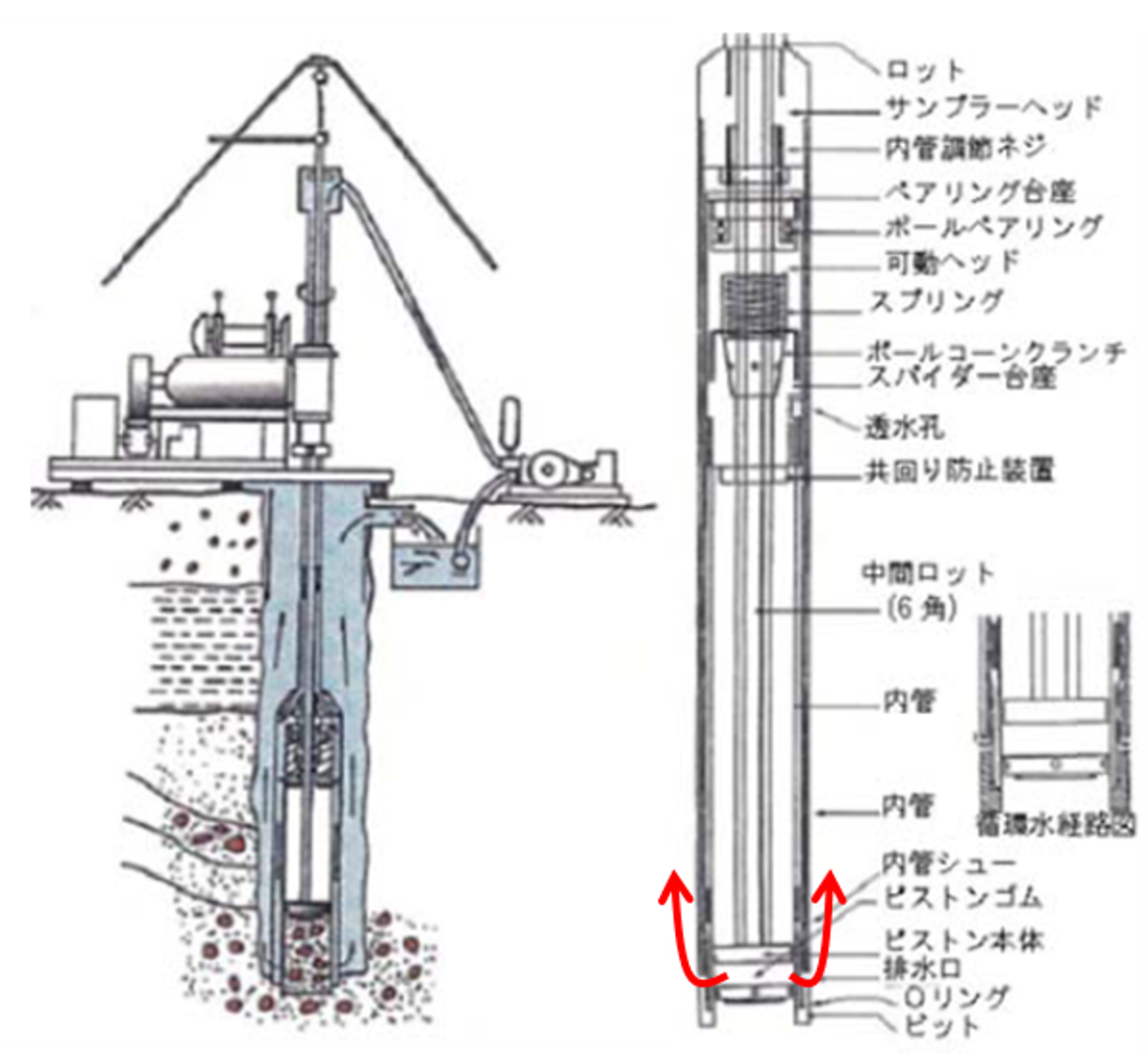

Diagram from Okabe (1924) |

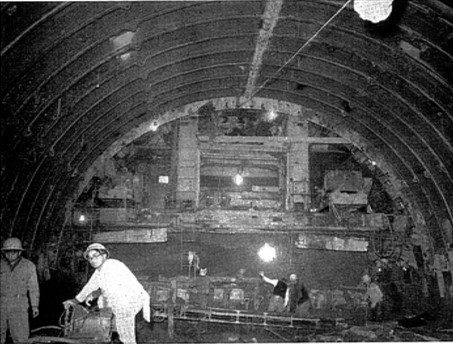

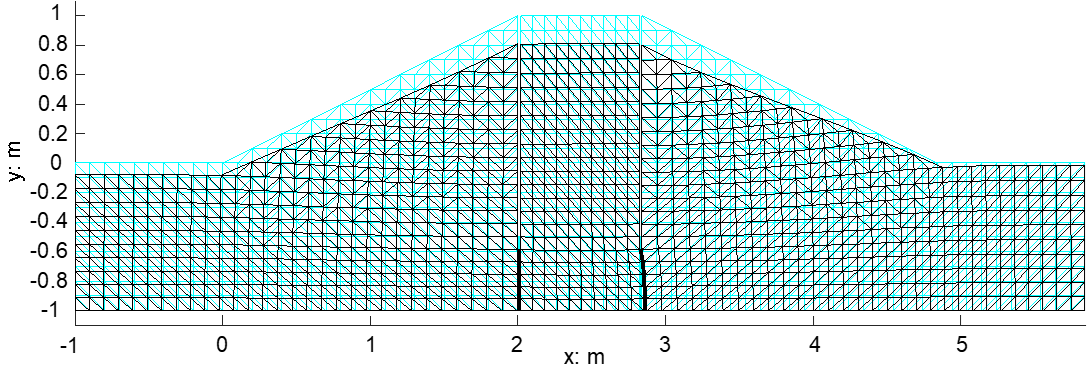

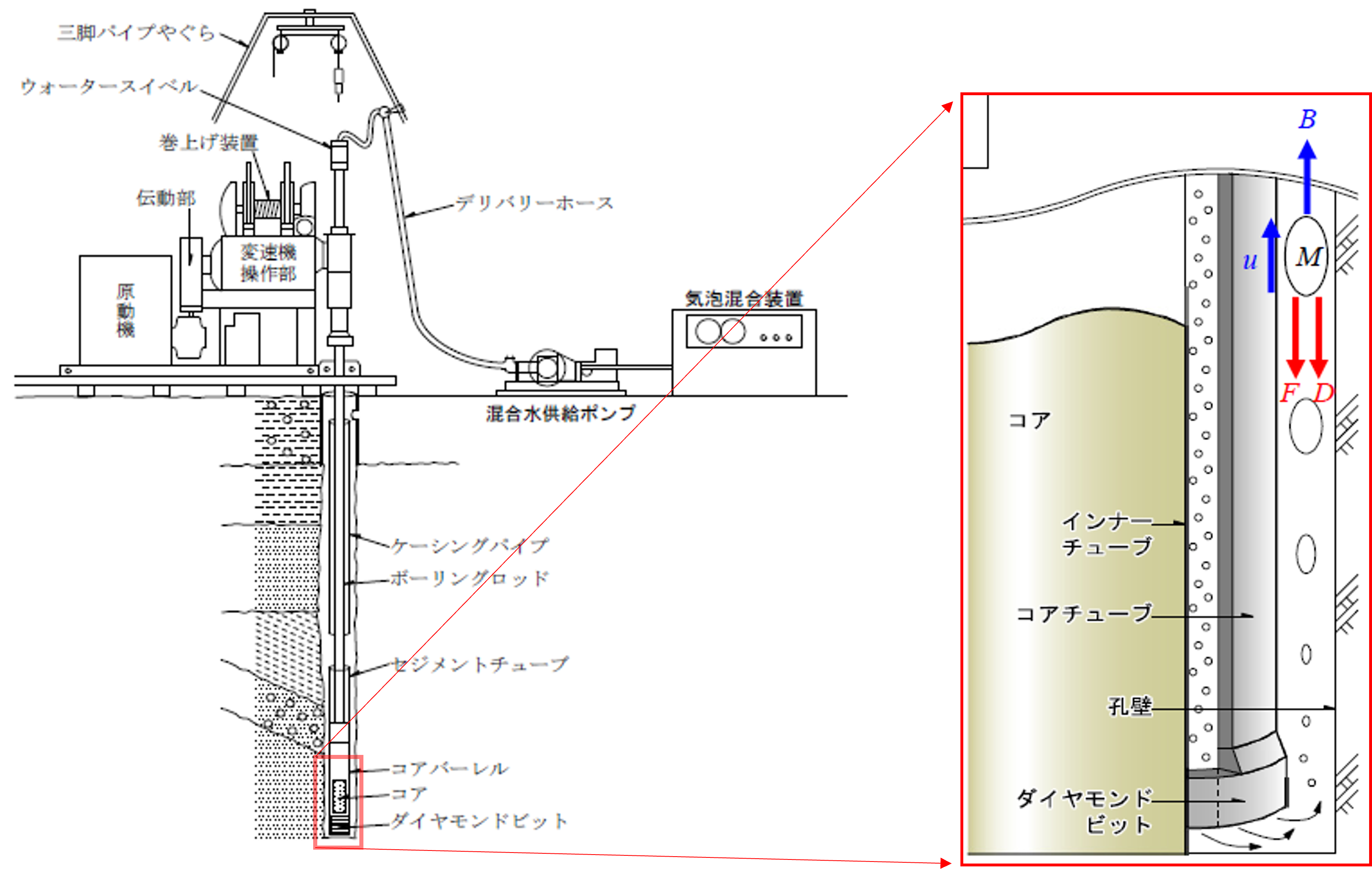

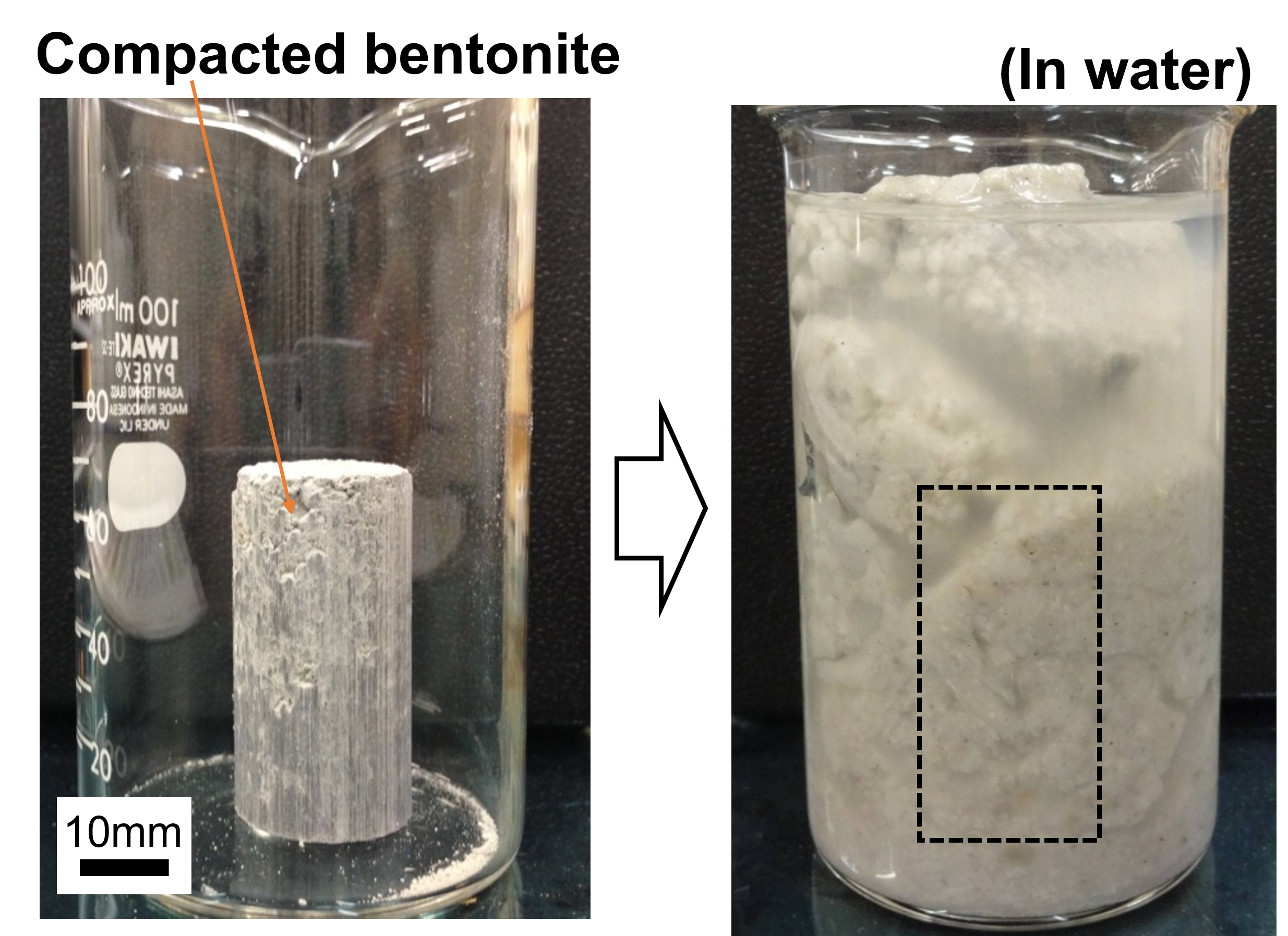

The first development of a resonant column device is credited to Dr. Iida and his group in the 1930s (Ishimoto & Iida, 1936; 1937, Iida, 1938), who recognized the importance of what we call ‘site effects’ on amplification of seismic motions and saw a need for obtaining soil stiffness and damping properties dynamically. This innovation directly or indirectly led to blooming of laboratory soil dynamics research in the USA in the 1960s and 1970s, in which the principle of resonant column testing was adopted in various machine designs, and eventually to stipulation in ASTM D4015. It is refreshingly impressive to see that Iida’s papers, published in bulletins of Earthquake Research institute, University of Tokyo, are all written in English.

Mononobe-Okabe theory on seismic earth pressure originates from a suite of papers that appeared in the 1920s, authored independently by Dr. Nagaho Mononobe (Mononobe & Matsuo, 1929) and Dr. Sabro (in his own spelling) Okabe (Okabe, 1924), both working for the Department of Home Affairs (Naimushō) of Japanese Government. The theory is based on limit equilibrium with pseudo-static approach to the seismic inertia force. Even today, the theory has a place in many official design codes in Japan and elsewhere.

Ishimoto, M. & Iida, K. (1936): Determination of elastic constants of soils by means of vibration methods. Part 1. Young’s modulus. Bulletin of Earthquake Research Institute, University of Tokyo 14 632-657.

Ishimoto, M. & Iida, K. (1937): Determination of elastic constants of soils by means of vibration methods. Part 2. Modulus of rigidity and Poisson’s ratio. Bulletin of Earthquake Research Institute, University of Tokyo 15 67-85.

Iida, K. (1938): The velocity of elastic waves in sand. Bulletin of Earthquake Research Institute, University of Tokyo 16 131-145.

Mononobe, N. & Matsuo, H. (1929): On the determination of earth pressure during earthquake. Proceedings of World Engineering Conference, Tokyo, 9 177-185.

Okabe, S. (1924): General theory on earth pressure and seismic stability of retaining wall and dam. Proceedings of JSCE 10 (6) 1277-1330.

More:

See the early papers on ERI website: https://www.eri.u-tokyo.ac.jp/en/publication/